High Expansion Foam

In the world of firefighting, versatility is key, and that’s precisely what High-Expansion Foam Concentrates bring to the table. These specially designed firefighting agents are your ultimate allies when it comes to combating different types of fires, whether it’s Class A, Class B, or even fires involving liquefied natural gas (LNG).

The Power of Expansion:

One of the standout features of these foam concentrates is their remarkable ability to expand. Think of it as turning a small pebble into a colossal mountain. When you mix the foam concentrate with water, the magic happens. For instance, take 100 liters of water and add the right premix solution, and you’ll witness the transformation of that humble mixture into a whopping 40,000 liters of finished foam. This incredible expansion ratio is what makes these foams stand out, with a ratio of 400 times its original volume.

Swift and Effective Fire Suppression:

When the heat is on and a fire is raging, speed and effectiveness are of the essence. High-Expansion Foam Concentrates excel in this department. They spread rapidly, covering a vast area in a short span of time. Not only do they extinguish the fire, but they also act as insulators, keeping the heat at bay. This dual action is essential for ensuring that the fire doesn’t reignite.

The Creation Process:

Ever wondered how this foam is made? It’s a fascinating process involving specialized equipment known as high-expansion foam generators or high-expansion fire extinguishing systems. These systems use a technique that involves infusing the foam concentrate with air. The result is high-expansion finished foam that flows directly from the foam discharge equipment. What’s even more remarkable is that it uses minimal water to create a significant volume of foam, which is great for conserving resources.

The Right Tool for the Job:

High-Expansion Foam Concentrates are like the Swiss Army knife of firefighting agents. They are ideal for addressing three-dimensional fires, flooding large surface areas, and filling cavities. These foams are particularly valuable when it comes to tackling dry product fires or in premises with mixed fire risks, which can include anything from burning solids (Class A) to flammable liquids (Class B). You’ll find them hard at work in various settings, such as stores, warehouses, aircraft hangars, distribution warehouses, tunnels, and even in the engine and pump rooms of marine vessels.

Safe and Environmentally Friendly Options

We understand the importance of safety and environmental responsibility. That's why High-Expansion Foam Concentrates come in two variants - one that is free of harmful chemicals, often referred to as synthetic fluorine-free foam (F3), and another that contains chemicals such as Aqueous Film-Forming Foam (AFFF) and Alcohol-Resistant Aqueous Film-Forming Foam (High Expansion Foam). Both variants are formulated to meet national and international safety standards, ensuring that they not only get the job done but do so without compromising safety or the environment.

Mixing It Up for the Ultimate Versatility:

Imagine having a toolbox filled with different tools for various tasks. High-Expansion Foam Concentrates offer a similar kind of versatility. You can mix these foams with fresh water or even seawater, allowing you to adapt to different scenarios and fire types. It's like having a versatile recipe book, and you get to choose the ingredients based on the specific firefighting situation.

High-Expansion Foam Concentrates are indispensable assets in modern firefighting. Their extraordinary expansion properties, coupled with their adaptability, safety, and environmental consciousness, make them a crucial component in the quest to suppress and control fires effectively. If you're in the market for a firefighting hero that offers speed, efficiency, and versatility, look no further. High-Expansion Foam Concentrates are here to save the day and protect what matters most.

USAFE GREEN High Expansion Foam is compatible with soft, hard, brackish or salt water. It can be used in Combination with Dry powder extinguishing agents either separately or as twin agent systems.

USAFE GREEN High Expansion Foam shall not be mixed with other manufacturers foam concentrate except for use in emergency situations.

| PRODUCT | AR – AFFF 1 x 3 | AR – AFFF 3 x 3 | AR – AFFF 3 x 6 |

|---|---|---|---|

| USE CONCENTRATION | 1% – 3% | 3% | 3% – 6% |

| SPECIFIC GRAVITY | 1.05±0.05 | 1.05±0.05 | 1.02±0.02 |

| pH @ 20oC | 7.5±0.5 | 7.5±0.5 | 7.5±0.5 |

| VISCOSITY @ 20oC | 1750±500 CST | 1750±500 CST | 1500±500 CST |

| FREEZING POINT | -2oC | -2oC | -2oC |

| POUR POINT | -1oC | -1oC | -1oC |

| STORAGE TEMPERATURE | +1.7oC MINIMUM 0 +50oC MAXIMUM | +1.7oC MINIMUM 0 +50oC MAXIMUM | +1.7oC MINIMUM 0 +50oC MAXIMUM |

| FOAM EXPANSION | LOW > 7 | LOW > 7 | LOW > 7 |

| 25% DRAINAGE TIME | 8 MINUTES 12 MINUTES | 8 MINUTES | 8 MINUTES 12 MINUTES |

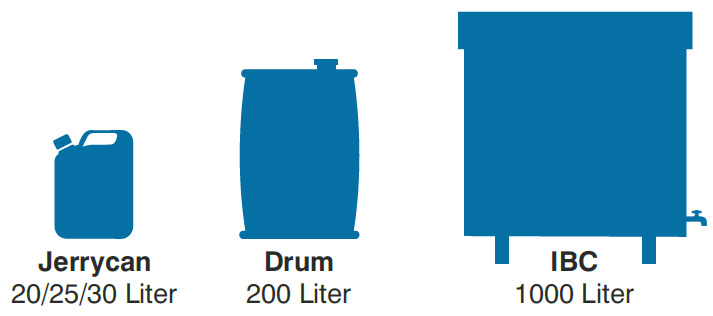

USAFE GREEN High Expansion Foam may be stored in its shipping container without change in its original physical or chemical characteristics. Shelf life is expected to be 10 years or more when stored at recommended temperatures and in original containers. It does not show signicant sedimentation or precipitation in storage or after temperature cycling. Freezing and thawing have no effect on performance and the concentrate proportions satisfactorily in ordinary equipment at emperatures above 1.7ºC. Synthetic foam concentrates should only be stored in stainless steel (Type 304L or 316), reinforced breglass polyester with a vinyl ester resin internal layer coating or plastic containers.