Hazmat Foam (Vapor Supression Foam)

Imagine you’re in need of a dependable ally in your quest for chemical safety. That ally is HAZMAT Foam, a remarkable product that’s like having a superhero by your side for safeguarding against hazardous chemicals.

Why You Need HAZMAT Foam

When you’re working with chemicals, there’s always a risk that they might transform into harmful gases, a situation you absolutely want to avoid. Standard firefighting foam can’t effectively combat this, but HAZMAT Foam can. It’s the solution that prevents those perilous gases from escaping into your workspace.

Where HAZMAT Foam Comes to the Rescue

You might wonder where this incredible product can be of assistance. The answer is everywhere you encounter chemicals that could pose a threat. Whether it’s in chemical storage areas, loading zones, or locations where chemical processing occurs, HAZMAT Foam is your go-to choice.

Tailoring HAZMAT Foam for Different Chemicals

Tackling Reactive Products: These are the chemicals that can be a bit unpredictable. For such substances, we rely on medium expansion foam. The process is straightforward—apply a minimum of 20 liters of foam per square meter every minute. Ensure that the foam maintains a thickness of about 50 centimeters (20 inches) until the chemicals are safely managed.

Safely Managing Non-Reactive Products: Some chemicals are less temperamental, but you still need protection. For these situations, we use NEUTRAL PLUS foam, mixed at a 6% concentration, along with medium expansion. Apply at least 10 liters of foam per square meter every minute. Keep the foam layer at a consistent 50-centimeter (20-inch) thickness until the chemicals are under control.

USAFE GREEN HAZMAT FOAM: Your Eco-Friendly Partner in Safety

Now, picture having an environmentally conscious partner in your quest for chemical safety. That partner is USAFE GREEN HAZMAT FOAM. This eco-friendly foam concentrate is composed of safe ingredients and is compatible with various types of foam-generating equipment. Its mission is to cool things down and suppress those harmful chemical vapors.

The Range of Chemicals USAFE GREEN HAZMAT FOAM Works On

Think of USAFE GREEN HAZMAT FOAM as the guardian against hazardous materials, capable of handling a wide spectrum of substances. It's your trusty companion for dealing with acids, bases, and even the more challenging, flammable, or odorous liquids. Rest assured, it will keep you safe and secure when confronting a diverse array of chemicals.

As a user, you can have peace of mind knowing that HAZMAT Foam and USAFE GREEN HAZMAT FOAM are your dedicated allies in ensuring safety and well-being when working with chemicals. These products are like having your own team of chemical safety superheroes, guarding your every move and keeping you protected in all scenarios.

USAFE GREEN HAZMAT FOAM is compatible with soft, hard, brackish or salt water. It can be used in Combination with Dry powder extinguishing agents either separately or as twin agent systems.

USAFE GREEN HAZMAT FOAM shall not be mixed with other manufacturers foam concentrate except for use in emergency situations.

| PRODUCT | HAZMAT FOAM 1 x 3 | HAZMAT FOAM 3 x 3 | HAZMAT FOAM 3 x 6 |

|---|---|---|---|

| USE CONCENTRATION | 1% – 3% | 3% | 3% – 6% |

| SPECIFIC GRAVITY | 1.05±0.05 | 1.05±0.05 | 1.02±0.02 |

| pH @ 20oC | 7.5±0.5 | 7.5±0.5 | 7.5±0.5 |

| VISCOSITY @ 20oC | 1750±500 CST | 1750±500 CST | 1500±500 CST |

| FREEZING POINT | -2oC | -2oC | -2oC |

| POUR POINT | -1oC | -1oC | -1oC |

| STORAGE TEMPERATURE | +1.7oC MINIMUM 0 +50oC MAXIMUM | +1.7oC MINIMUM 0 +50oC MAXIMUM | +1.7oC MINIMUM 0 +50oC MAXIMUM |

| FOAM EXPANSION | LOW > 7 | LOW > 7 | LOW > 7 |

| 25% DRAINAGE TIME | 8 MINUTES 12 MINUTES | 8 MINUTES | 8 MINUTES 12 MINUTES |

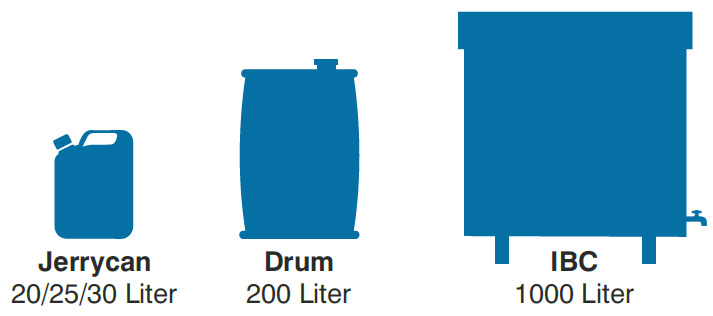

USAFE GREEN HAZMAT FOAM may be stored in its shipping container without change in its original physical or chemical characteristics. Shelf life is expected to be 10 years or more when stored at recommended temperatures and in original containers. It does not show signicant sedimentation or precipitation in storage or after temperature cycling. Freezing and thawing have no effect on performance and the concentrate proportions satisfactorily in ordinary equipment at emperatures above 1.7ºC. Synthetic foam concentrates should only be stored in stainless steel (Type 304L or 316), reinforced breglass polyester with a vinyl ester resin internal layer coating or plastic containers.